How many garage doors or garage door openers does a homeowner buy in his or her life? According to statistics, one or two… or a few more if this person needs to move more often than the norm because of work or other obligations.

To help you better understand the language used in the world of garage doors, here is a basic introduction to the most used terms. This will help you more clearly understand what garage door specialists tell you if they are repairing your door, or if they suggest you get a new door. In this blog, we will focus on the components that make up a garage door system.

The door itself

It’s not the terms about the door as such that are difficult to understand. Nonetheless, here are the basic ones:

- Almost all garage doors sold in North America are sectional, overhead doors that retract along the ceiling of the garage.

- These doors are made up of sections, usually 4, with individual heights varying between 18 and 24 inches (46 to 61 cm).

- The heights of residential doors range between 6 and 8 feet (1.8 and 2.4 m). Widths vary from 4 feet for sheds up to 18 feet for double garages (1.2 to 5.5 m).

- Their thicknesses range from 1 3⁄8 to 2 inches (35 to 51 mm).

- Garage doors come both insulated and non-insulated. When they are insulated, it is with plastic, polystyrene or polyurethane insulation. R factors may vary between R‑6 to R‑18.

- The most common exterior material is galvanized steel. Also seen are wood, fiberglass and PVC doors. In addition, there are ones in glass with extruded aluminum frames for modern and contemporary style homes.

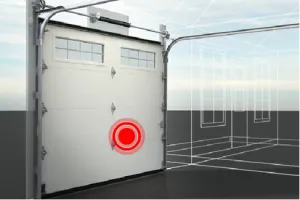

The hardware system

The terminology becomes more complicated behind the door. It takes numerous small parts working together to ensure that the whole thing operates properly.

- The spring system: Also called the counterweight system, it’s what allows you to open a garage door with just one hand. A well-balanced door weighs between 8 and 10 lb. (3.5 and 4.5 kg). There are two models, torsion and extension. The first is a spring system shaped like a coil, inserted in a steel shaft and located over the door. The second, extension, is also a coil spring system, but they are placed over the horizontal tracks. As their names say, when the door closes, the springs extend. A torsion system requires a little more space over the door (12 in. / 30 cm) to operate the door. An extension system, a little less (8 in. / 20 cm). Both systems have a service life of about 5 to 7 years before they stop working optimally or break.

- The hinges: These form the joints that allow the door sections to bend and retract up along the ceiling as the door opens. For large garage doors (16 ft. / 4.9 m), it is advised to use double hinges to adequately hold the door when it stays in its open position. They are located at the end of the door sections.

- The rollers: There are basically 3 types: steel, black nylon and reinforced nylon in white. The last two are the quietest due to the nylon. For steel rollers, it’s important to know how many bearing they have, as the more, the better. And remember one important thing – rollers should roll in their tracks, not slide.

- The lifting cables: These are braided steel wires that are calibrated according to the total weight of the door. The bigger the door, the stronger the cables.

- The tracks: There are vertical and horizontal ones. The thickness of the steel that composes them is important. The thicker the steel, the less chance the tracks will have the tendancy to twist or tilt under the weight of the door.

- Reinforcement struts: They are used to support double garage doors when they are left open for long periods.

- Thickness of the steel used: For all these components, note that their thickness is measured in gauges. The lower the value, the thicker the steel. Thus, 14‑gauge steel is thicker (around 37%) than 18‑gauge steel.

- Galvanized steel: The steel used for the hardware components is galvanized, but at a level according to the normal use it was intended. There are some steel components (ex.: springs) with a higher level of galvanization for very humid locations.

The weatherstripping system

There is a tendency to overlook this part. However, weatherstripping is as important as the door insulation.

- Weatherstripping between door sections: Some garage doors, like those from Garaga, come equipped with triple-contact weatherstripping and a thermal break, which stops the cold from passing through this part of the door.

- Exterior frame weatherstripping: This is very important so its quality should be verified. In the case of PVC, it is recommended to check its flexibility during cold weather. In general, the more you pay for weatherstripping, the better quality of PVC you will get.

- Bottom weatherseal: This is U‑shaped and slides into a PVC or aluminum retainer. Once again, this should be of superior quality. Those made from thermoplastic elastomer (TPE) are the most effective and remain flexible even at very cold temperatures.

To learn more…

If you would like to know more about garage doors, contact a garage door specialist in your area.

This specialist can send you a detailed quotation by email, or happily visit you at your home to explain the full range of garage doors on the market. They will also guide you on the best choice to make based on your tastes and budget. To get an idea what your house will look like with a new door, use a Design Centre like the one from Garaga, or get inspiration from their image gallery.

Add new comment