< Go back to all Commercial garage door models

G‑5000

- Steel

- Thickness: 1 ¾"

- 9 colors

- Polyurethane sandwich door

- R‑16 insulation

- Panel design: Grooved

Insulation options

G-5138: R‑12, Thickness: 1 3⁄8"

G-5200: R‑18, Thickness: 2"

Features and benefits

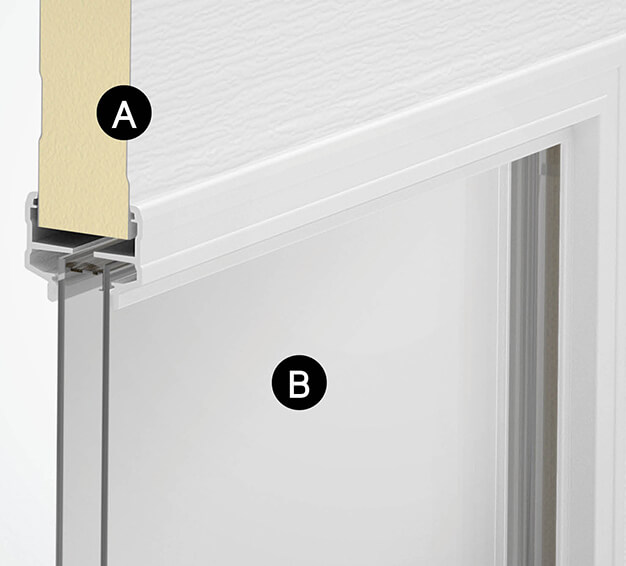

A

High-pressure injected polyurethane

- Stronger and more energy-efficient insulation

- Solidly bonded to the steel sheets providing a section that is resistant to flexion.

B

Sealed thermo-pane windows

- Optimize insulation and reduce seal failures with galvanized steel spacer technology

- Ensure a long lasting and refined appearance with one-piece molded polypropylene window frame.

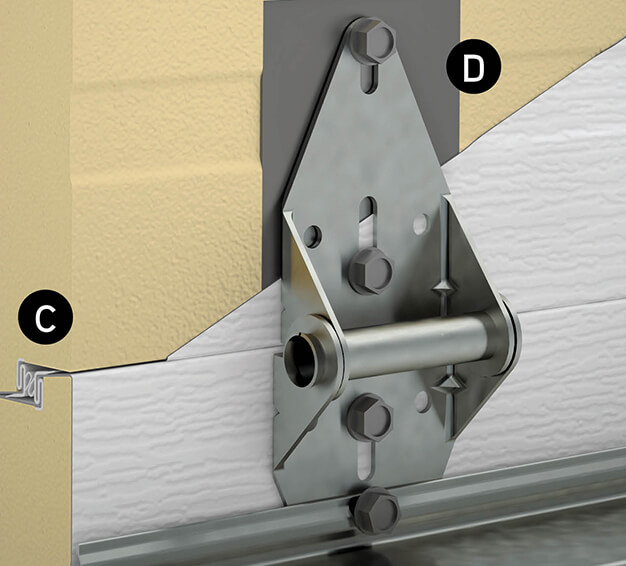

C

InterlokTM triple-contact joints

- Sections are strengthened by 2 steel walls joined together with mechanical interlocking joints which are more solid than just two bonded walls.

- Mechanical thermal breaks which are more efficient compared to thermal breaks made with glue.

-

Triple-contact joints provide 2 times more weathertightness than those of the competition.

D

Metal reinforcement plates

- Provide stronger fastening for hinges and struts. These 14-gauge plates are 2 times thicker than 20-gauge plates used by other manufacturers.

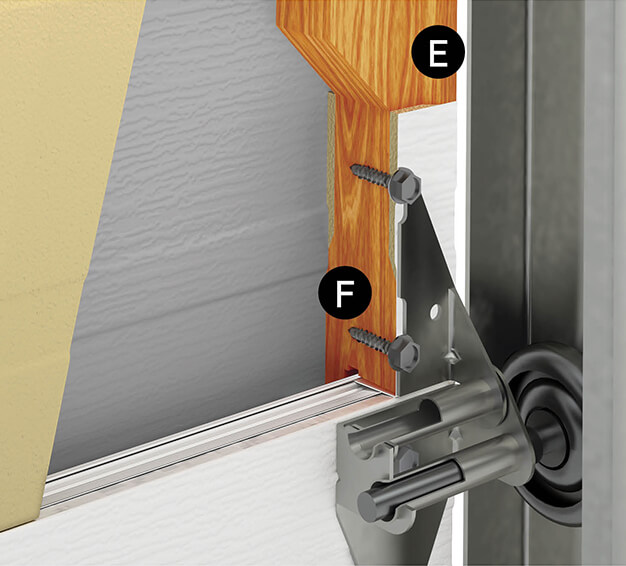

E

Wood end blocks

-

Provide a thermal break that is more effective than steel end caps which form a thermal bridge.

- Structural elements of the sections, the kiln-dried pine wood end blocks are installed at the outer ends of the section. They are stronger than insulation covered with a steel cap.

F

Lag screw system

- Provides much better fastening of the end hinges. The lag screws engage 8 threads into the wood, compared to a self-tapping screw going through a steel end cap engaging only about 2 or 3 threads.

Our technical department

We can provide budgetary pricing for your projects and your customers’ ones.

Panel construction

1

Steel walls

- 26/26-gauge, G60 hot-dipped galvanized steel with five coats of protective finish.

- Baked-on polyester paint. Can be repainted.

- Woodgrain finish on both sides of the door.

- Same quality of corrosion-resistant steel for interior and exterior faces.

2

Insulated door with high-pressure injected polyurethane foam ensuring a high thermal-resistance rating and the solidity of a composite material.

- G‑5000: 1 ¾" (44.5 mm), R‑16 (RSI 2.8 or k= 0.357 W/m2K)

- G‑5138: 1 3⁄8" (35 mm), R‑12 (RSI 2.1 or k= 0.476 W/m2K)

- G‑5200: 2" (50 mm), R‑18 (RSI 3.2 or k= 0.313 W/m2K)

3

InterLokTM joints between each section:

- Mechanical joints ensure stronger sections with walls of each panel mechanically interlocked (not only bonded by the polyurethane).

- Mechanical thermal break avoids heat transfer between the interior and exterior walls of each section.

- Triple-contact joint prevents air infiltration.

4

U-shaped tubular bottom weatherstripping made of thermoplastic elastomer (TPE) ensures the weathertightness of the threshold. Remains flexible and watertight during cold weather, to -62°F (-52°C).

5

Wood end blocks made of kiln-dried pine (grade 4). With our lag screw system, ensure better fastening of the end hinges. They also provide a thermal break which prevents thermal bridging.

6

14-gauge steel reinforcement plates placed inside the door for solidly attaching hinges and struts.

Door weight:

G-5000: 1.90 lb/ft2 (9.3 kg/m2)

G-5138: 1.75 lb/ft2 (8.5 kg/m2)

G-5200: 1.95 lb/ft2 (9.5 kg/m2)

Panel design

Grooved

Sizes

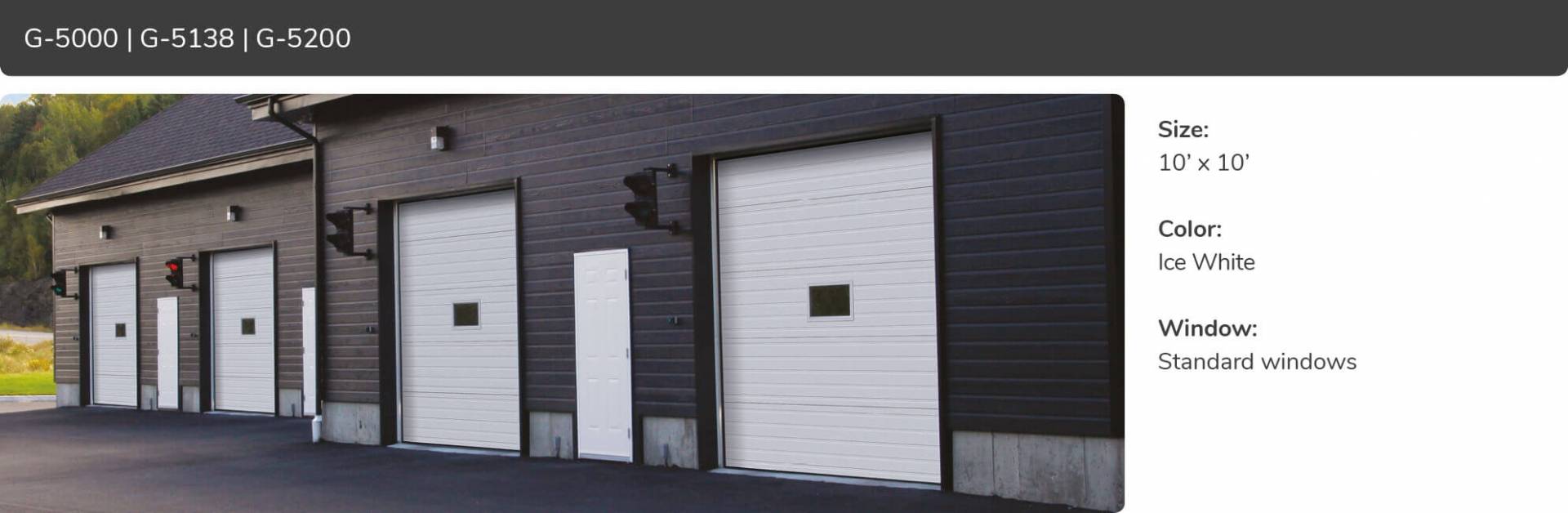

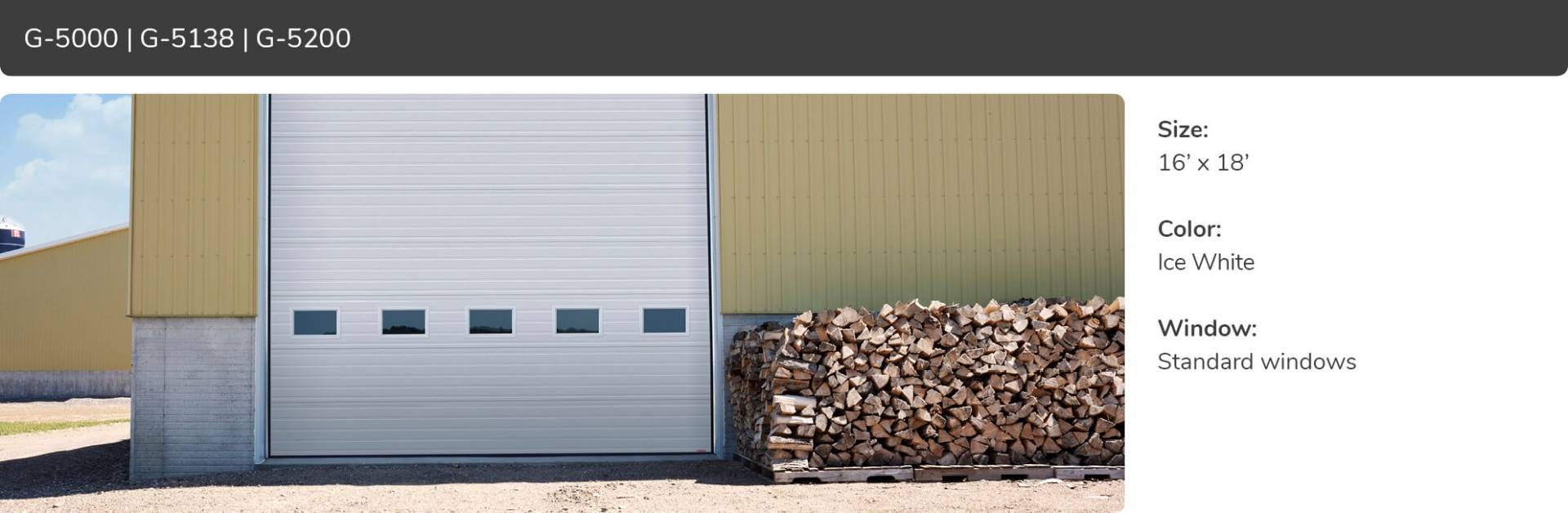

| G-5000 | G-5138 | G-5200 | |

| Widths

In 1" (25 mm) increments |

From 4' to 29'6" (1.2 m to 9 m) |

From 4' to 18' (1.2 m to 5.5 m) |

From 4' to 24' (1.2 m to 9 m) |

| Heights

In 3" (76 mm) increments |

From 6' to 24' (1.8 m to 7.3 m) |

From 6' to 18' (1.8 m to 5.5 m) |

From 6' to 24' (1.8 m to 7.3 m) |

Sizes

Warranties

- 10 years against any perforation of steel due to rust

- 10 years on the wood and blocks against cracking and rot

- 10 years against delamination of the steel skin from the polyurethane foam

- 1 year on other door components

- 10 years against seal defects on Standard windows

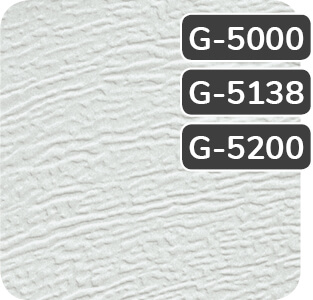

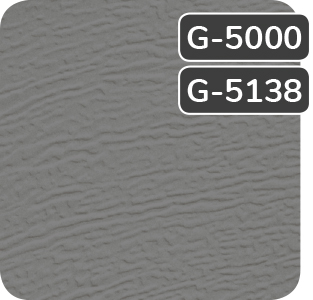

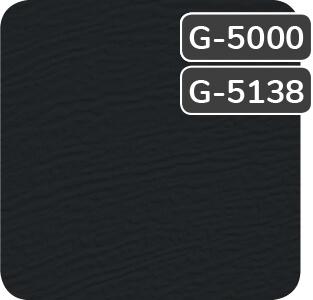

Colors

Standard

Ice White

Desert Sand

Claystone

Dark Sand

Moka Brown

Premium

Charcoal

Evergreen

Black

Silver

Premium Colors: small additional fees apply.

The accuracy of colors on the website may vary depending on your screen settings. To see the true colors, please contact your local Garaga dealer for a sample.

Windows

Standard windows

Available for doors:

G-5000

G-5138

G-5200

Sizes

21" x 13" (533 mm x 330 mm)

Glass

- Thermopane windows:

- G‑5000: Clear, Sandblasted, Tempered, Laminated or Tinted

- G‑5138: Clear or Sandblasted

- G‑5200: Clear, Tempered 2 sides, Low‑E, Low‑E Tempered 2 sides

- Single glass (3 mm):

- G‑5000 and G‑5138: Clear or Sandblasted

Frame colors

- G‑5000: White, Desert Sand, Claystone, Dark Sand, Brown, Evergreen, Black and Charcoal

- G‑5138: White, Desert Sand, Claystone, Dark Sand and Brown

- G‑5200: White

G-4400 Sections (Full Vision)

Available for door:

G-5000

Glazing options

- Windows are available in ⅛" Single Pane or ⅞" Thermopane in Glass, Polycarbonate or Acrylic. Also in ⅞" Fluted Polycarbonate in Thermopane and ⅝" Triple Wall Structure. The option of tempered glass is available in some cases.

Colors

White, Anodized, Black, Desert Sand, Claystone, Dark Sand, Moka Brown, Charcoal, Evergreen

For more details, see the G‑4400 Windows section or contact your Garaga dealer for other questions.

G‑5000 | G‑5138 | G‑5200

Hardware

Steel tracks

- 2” (50 mm), 13-gauge or 14-gauge

- 3” (76 mm), 12-gauge

Hardware systems and options

Learn more about:

Documents to download

Technical drawings

Revit file G-5000 | G-5138 | G-5200 (.rfa file)

Technical Drawing G-5000 (.dwg file)

Technical specification G-5000

Technical Drawing G-5138 (.dwg file)

Technical specification G-5138

Technical Drawing G-5200 (.dwg file)

Brochure

LEED Projects

Garaga can provide the required information to obtain a LEED project.

Recycled material content of our steel is:

- 25% post industrial

- 20% post consumption